MEETING IT THROUGH INNOVATIONS IN PRODUCTS AND PROCESS

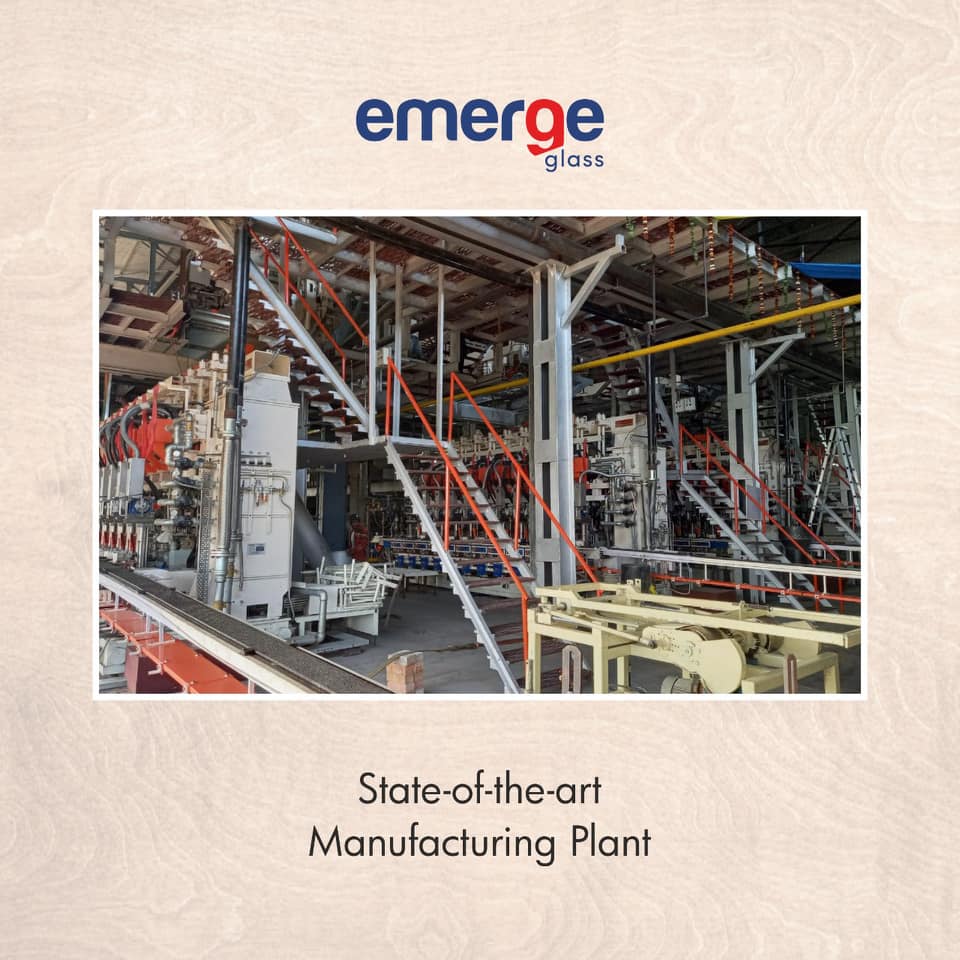

Emerge Glass has established its state of art

manufacturing unit with most advanced

technology which makes it the most fuel efficient

plant with longest furnace life. The manufacturing

excellence, which is a blend of upgraded

technology and innovation.

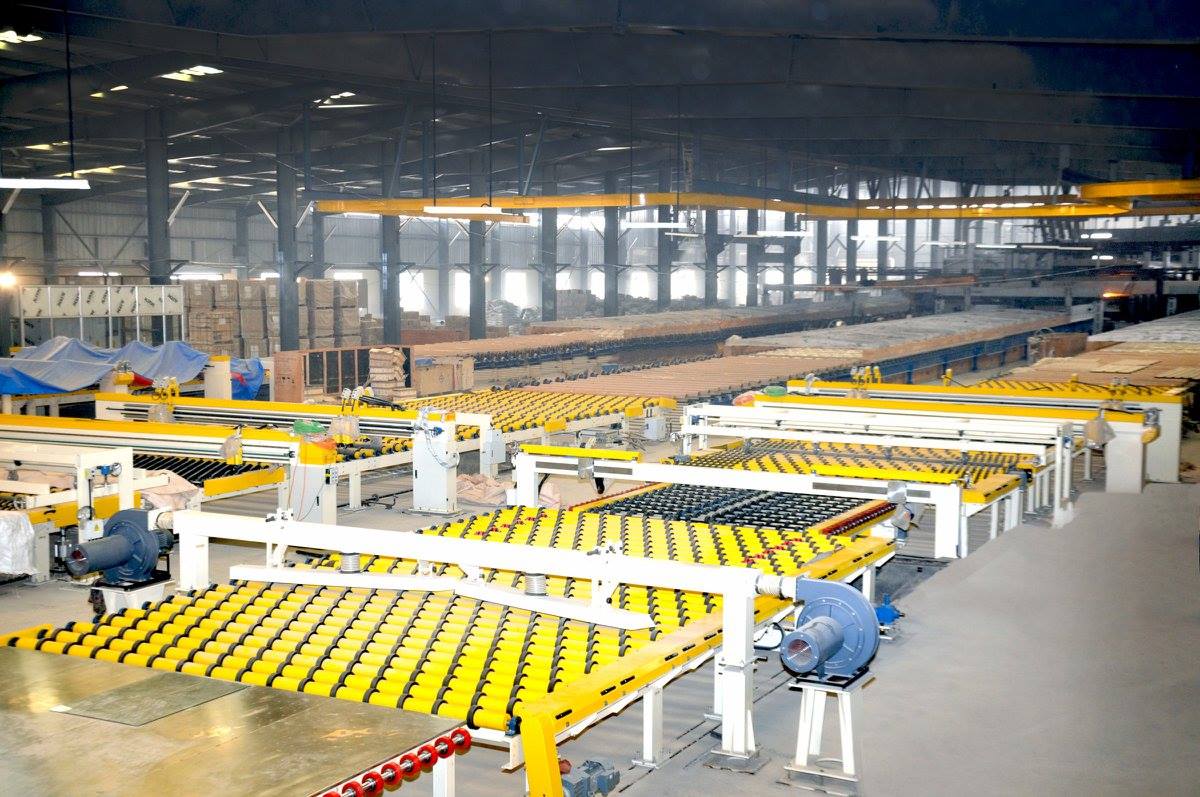

Our robust infrastructure is the key driver of our financial performance and growth and our infrastructure model ensures delivery of

quality.

- 210 MT production capacity per day

- 1000 skilled professionals

- 80,000 Sqm state-of-the-art manufacturing facility

- 35,000 sqm built-up area

- 20,000 sqm green area.

SUPPORT FROM BEST I.S. MACHINE MANFACTURERS- EMHAT IN FOLLOWING-

- Installation supervision

- Commissioning

- Plant stabilisation

TRAINED AND EXPERIENCED TEAM -

We have recruited trained & experienced team members from leading Container Glass manufacturing companies It is just to ensure that there is clarity on Quality and Customer's requirement from the very beginning.

DESIGN AND DEVELOPMENT-

We have set up in-house Design and development studio to delight our customers with efficient product development and product re-engineering.

FORMING TECHNOLOGY:- FOUR ELECTRONICALLY DRIVEN IS M/CS FROM EMHART GLASS (SANJIN)

| Line 1 | Line 2 | Line 3 | Line 4 |

|---|---|---|---|

| Double Gob | Double Gob | Double Gob | Double Gob |

| 5" Centre | 4.25" Centre | 5" Centre | 5" Centre |

| 8 Section | 10 Section | 10 Section | 8 Section |

| For large & mid-size B&B/P&B | For 180 ml | For small size | For large & mid-size B&B/P&B |

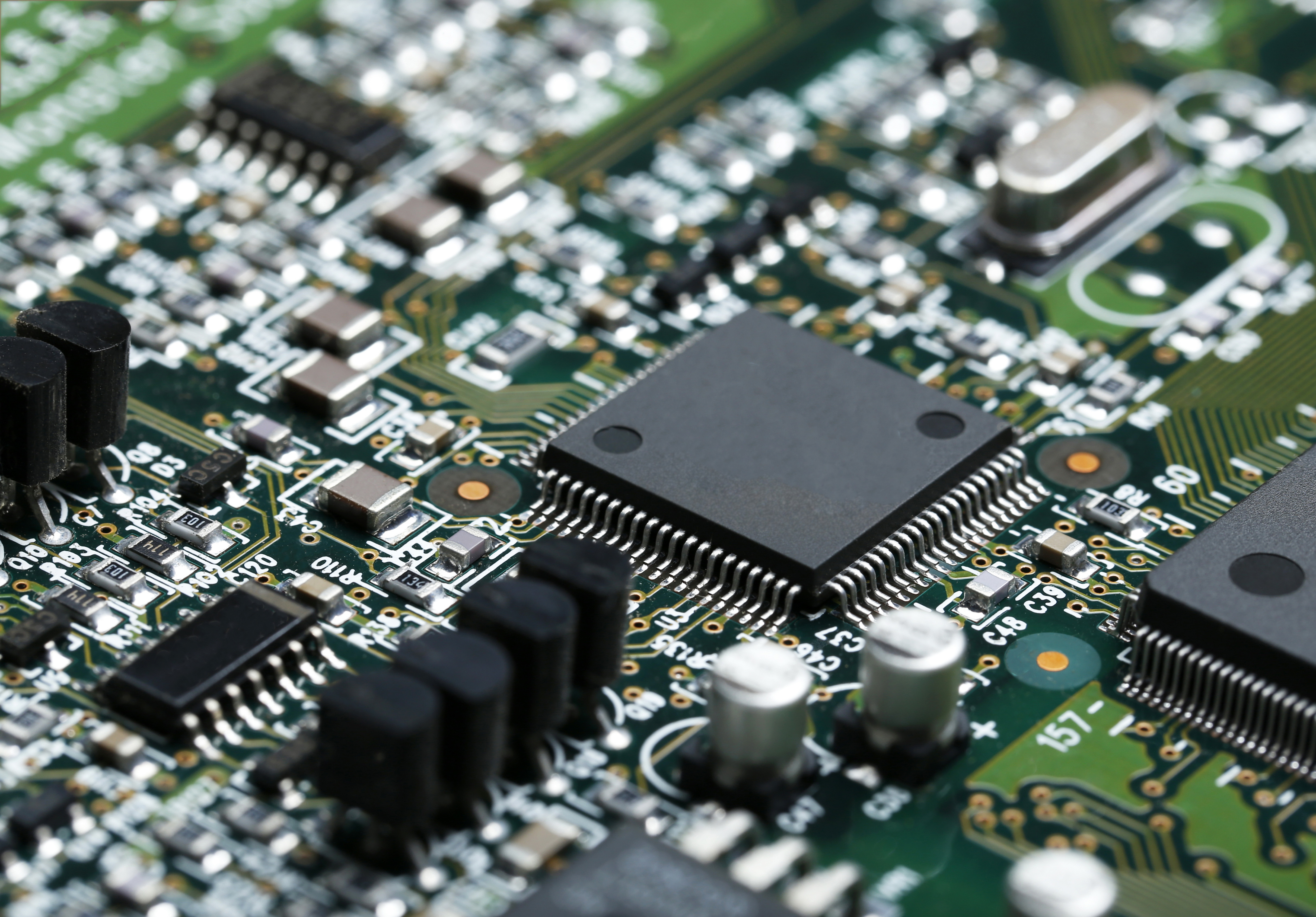

PLC Control-

- For better M/C control

- Section control

- Servo control for gob Distributor

- Servo Control for takeout mechanism and control for single pusher

Synchronous Drive System

- Better Feeder

- Main Conveyor

- Ware Transfer

- Cross Conveyor and Stacker

© Copyright 2022 All Rights Reserved